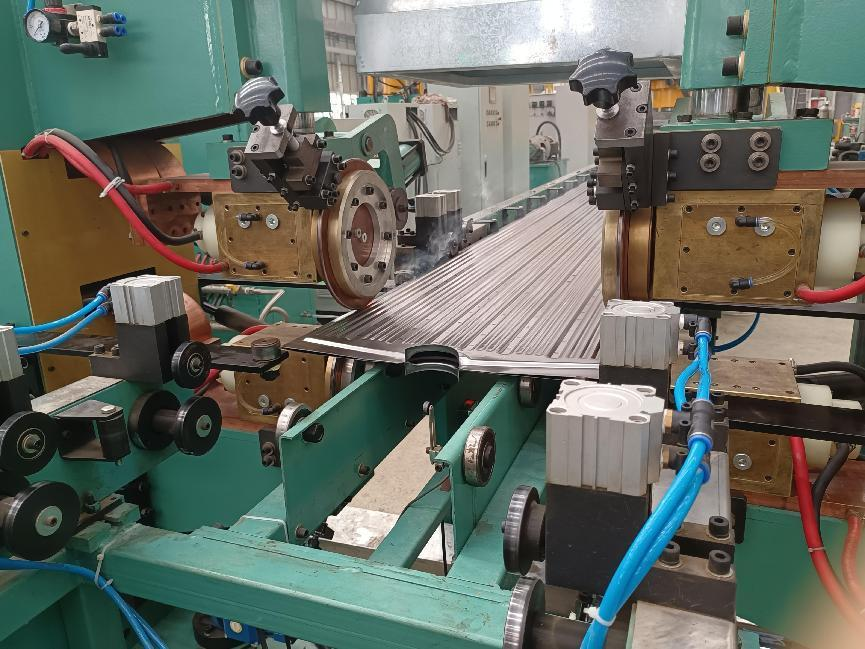

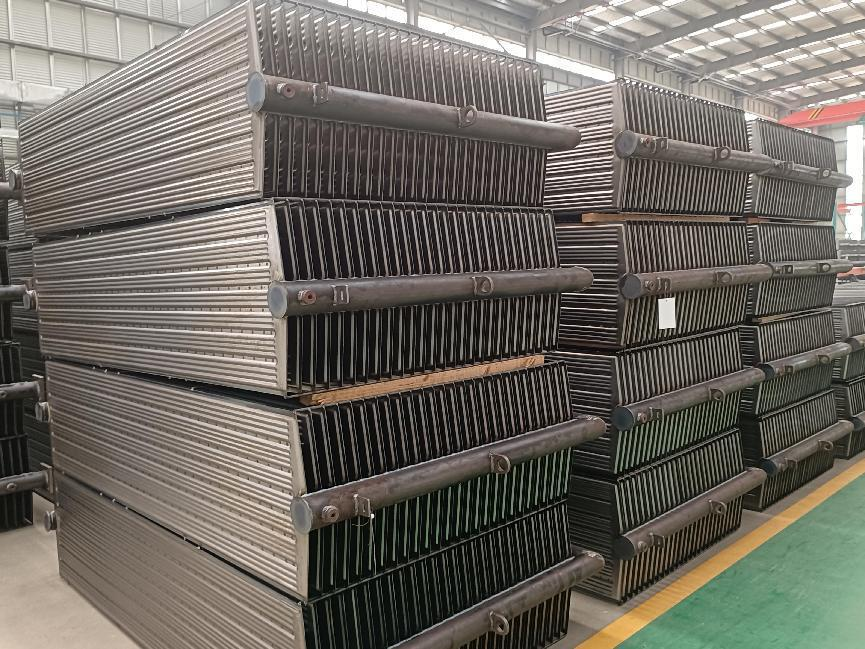

Full Automatic Transformer Radiator Fin manufacturing and making machine

I. General

Our automatic transformer radiator fin production line mainly absorb the technology and design of advanced company. The whole line is composed of automatic decoiler, roll former, multiple spot welder, side seam welding machine, head welding machine, head cutting machine, leveling,auto assembly machine etc. The radiator size is 520mm, panel length is 500mm-4000mm. It is with high degree of automation, and good forming, the general performance is near the level of international level as being the ideal processing equipment for radiator

manufacturers. The production line can be used on-line or also available separately

II. Work flow

Decoiling à roll forming à hydraulic press à multiple spot welding à side seam welding à head welding à head cutting à leveling à auto assembly

Equipment includes,

1. Hydraulic decoiler

2. Roll former for the sheet forming

3. Hydraulic press for head punching and cutting

4. Servo feeding conveyer

5. Multi-Spot Welding Machine

6. Side Seam Welding machine(Dual Welding)

7. Head Seam Welding Machine

8. Head cutting machine

9. Conveyers between the machines